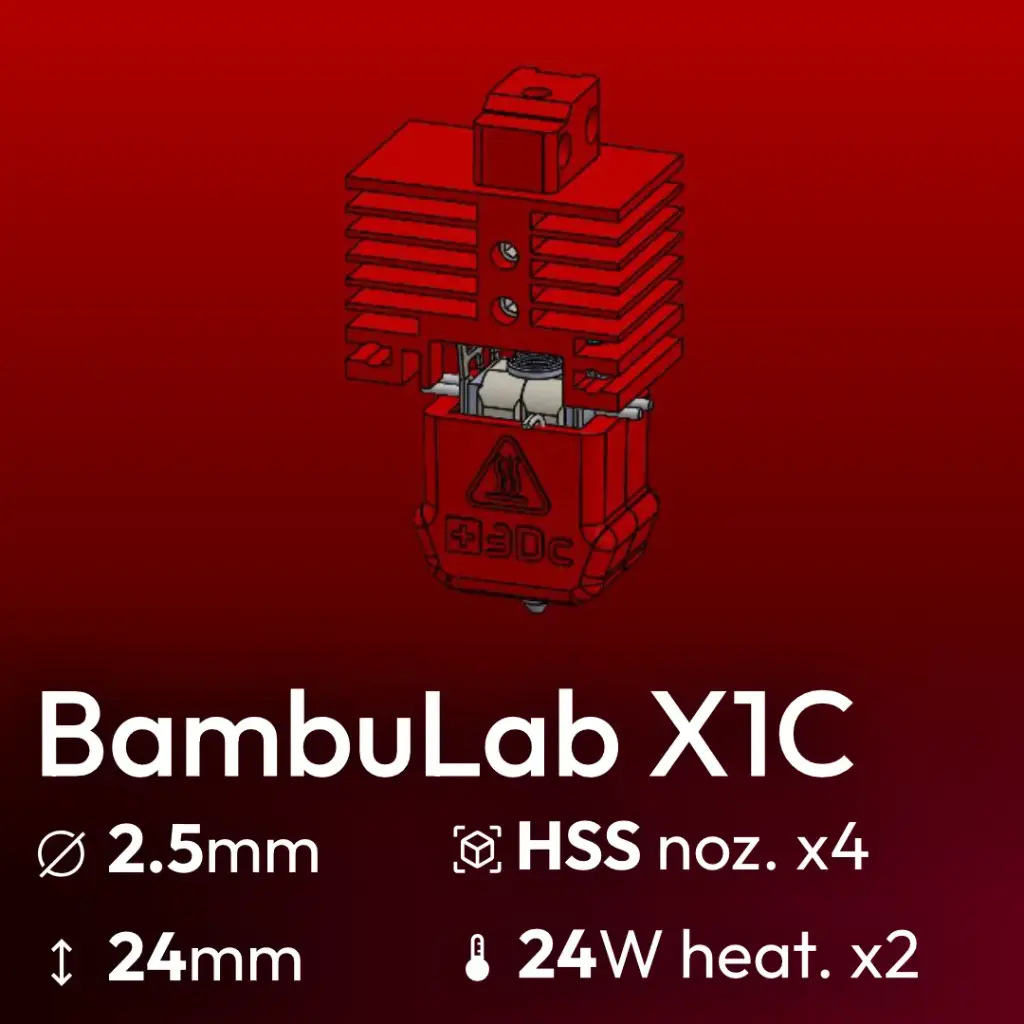

When it comes to 3D printing, the choice of nozzle can significantly impact your results, and 2.5mm nozzles made from hardened stainless steel are an exceptional option. These nozzles are meticulously crafted to endure the challenges posed by abrasive filaments and high-temperature environments, ensuring reliability and performance.

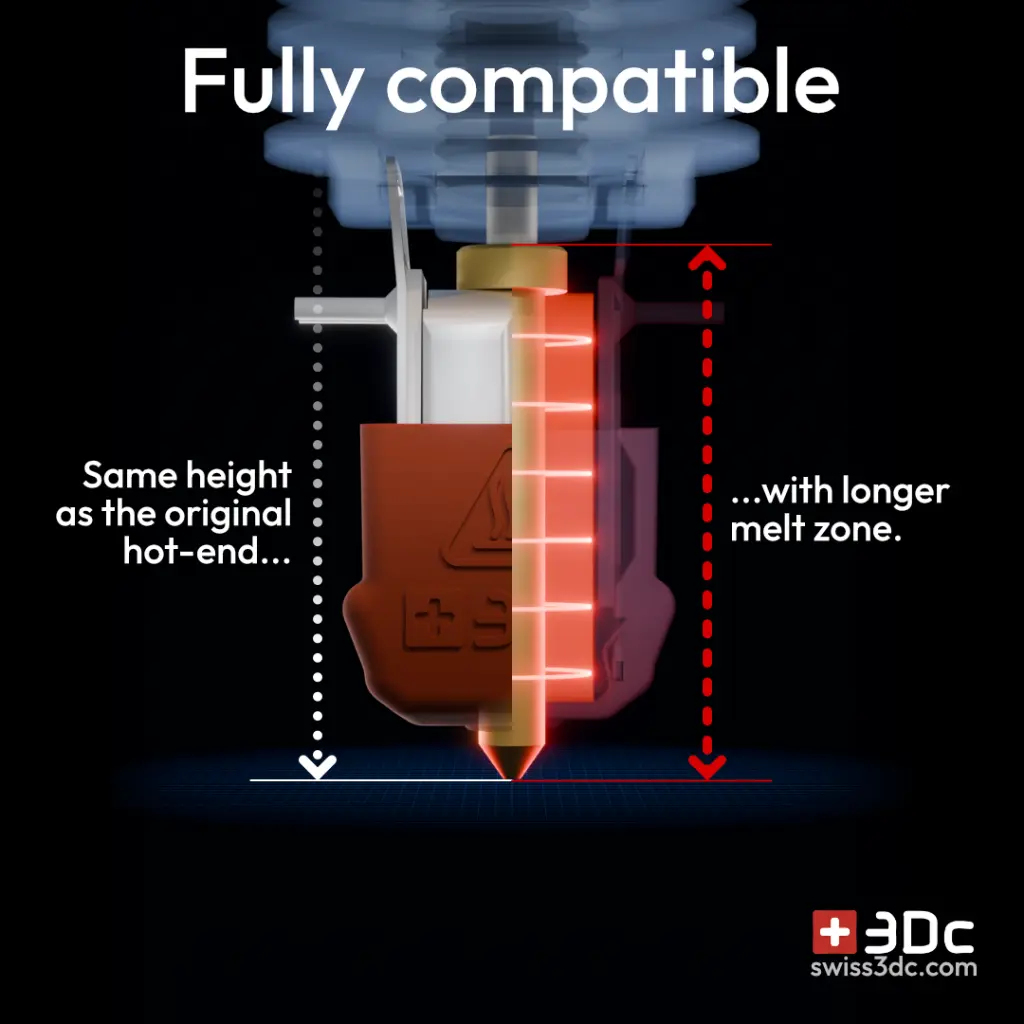

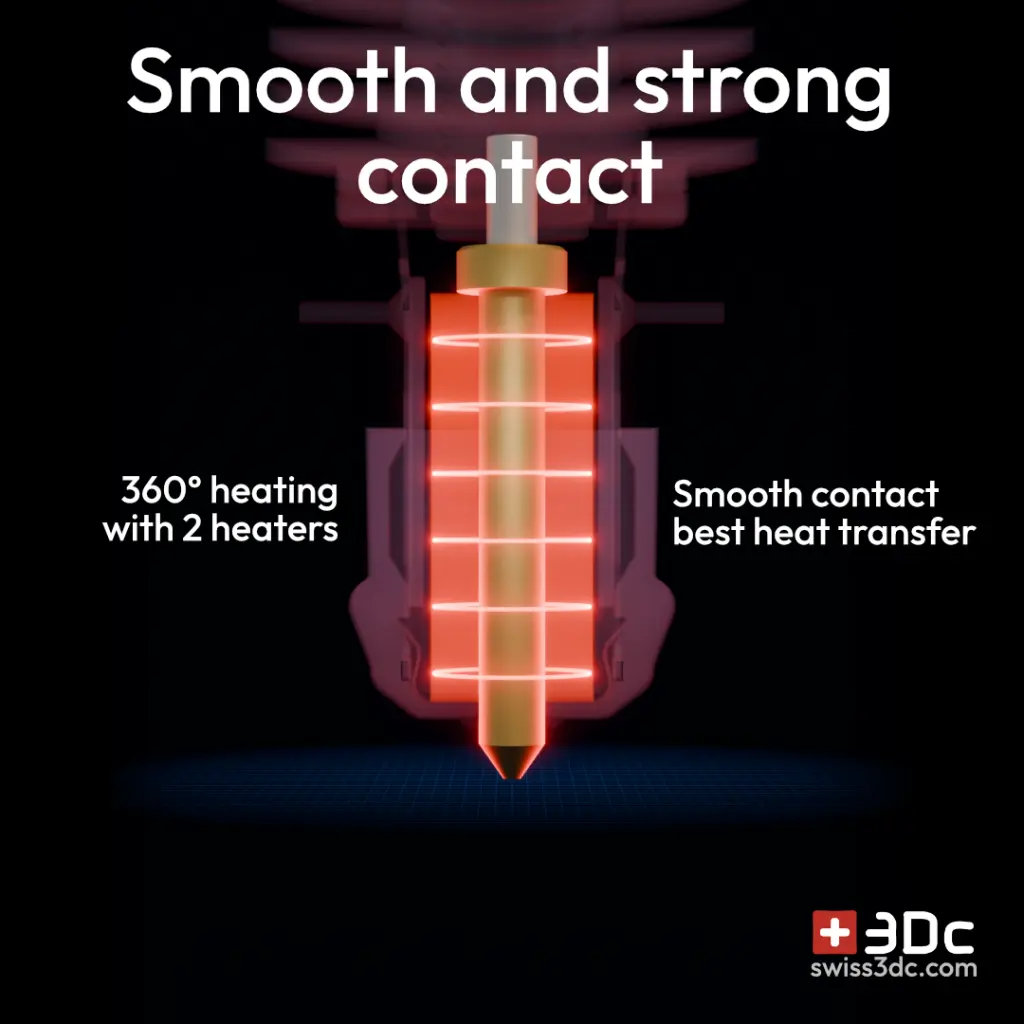

The 2.5mm body diameter is not just a number; it is a carefully considered design that reduces the thermal barrier, optimizing heat transfer despite the metal's lower thermal conductivity.

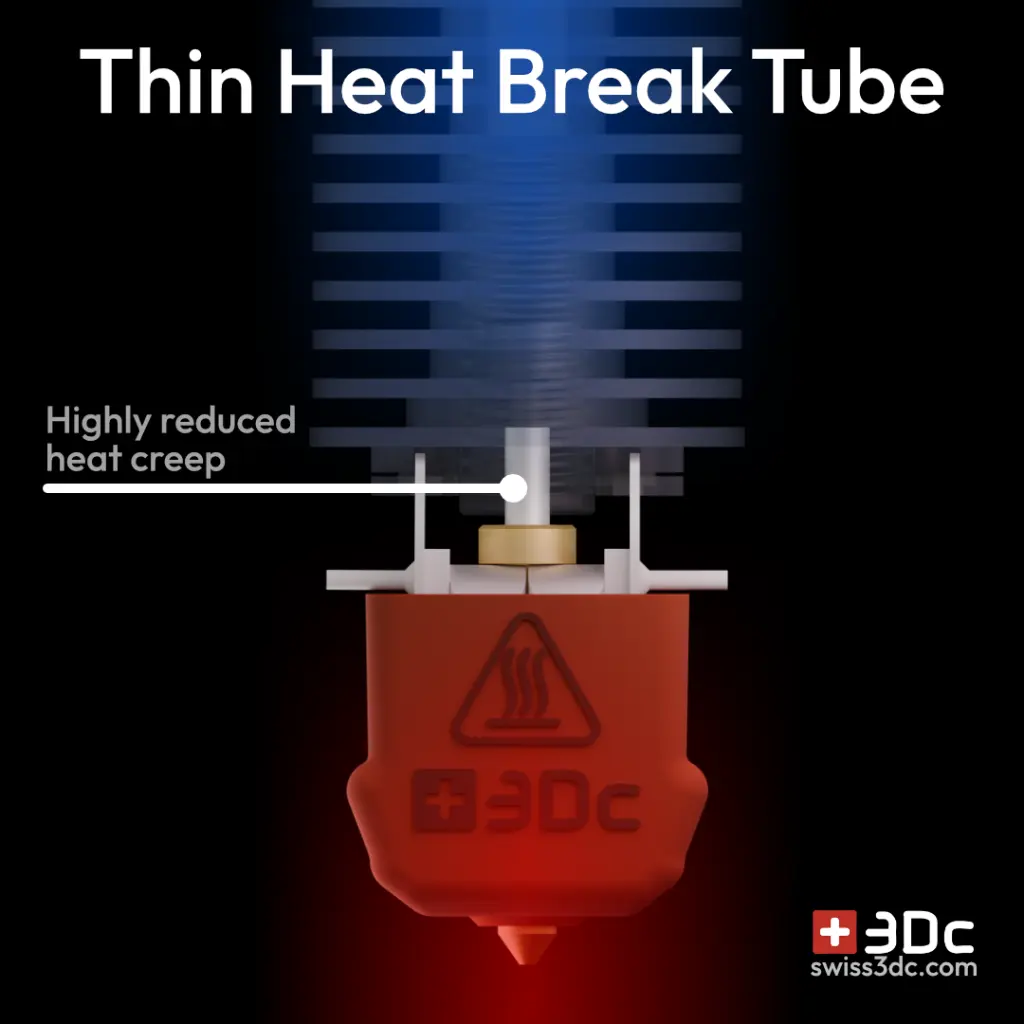

For those seeking consistent flow rates, a slight increase in the standard temperature by 5 to 10°C may be necessary with full hardened stainless steel nozzles, even a little more depending on the filament quality. This minor adjustment can make a significant difference in your printing outcomes.

It's important to note that while certain abrasive filaments can wear down hardened nozzles over time, the investment in high-quality stainless steel pays off in durability and performance.

-------

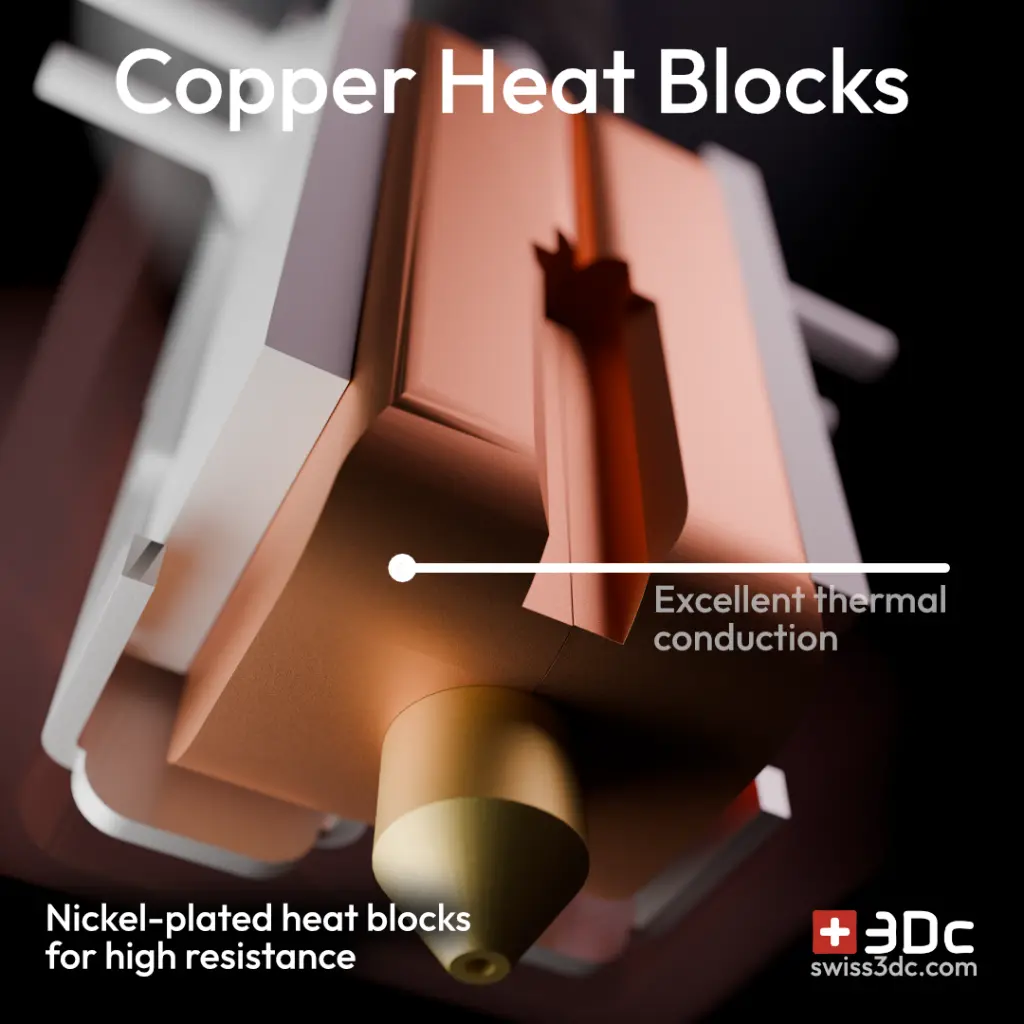

On the other hand, 3.0mm nozzles, typically made from brass and copper, excel in thermal conductivity but may lack the abrasion resistance needed for more demanding materials. They are ideal for use with filaments like PLA and PETG, but for those looking to push the boundaries of their printing capabilities, the 2.5mm option is the clear choice.

Hardened stainless steel nozzles with a copper sleeve (HSSC) provide seamless compatibility with brass nozzles, both featuring a 3.0mm body diameter, allowing for effortless interchangeability. This versatility is a game-changer for any serious 3D printing enthusiast.

With a 3.0mm body diameter, these nozzles require corresponding heat blocks to be 3mm as well, ensuring optimal performance. Choosing the right pairing is essential.