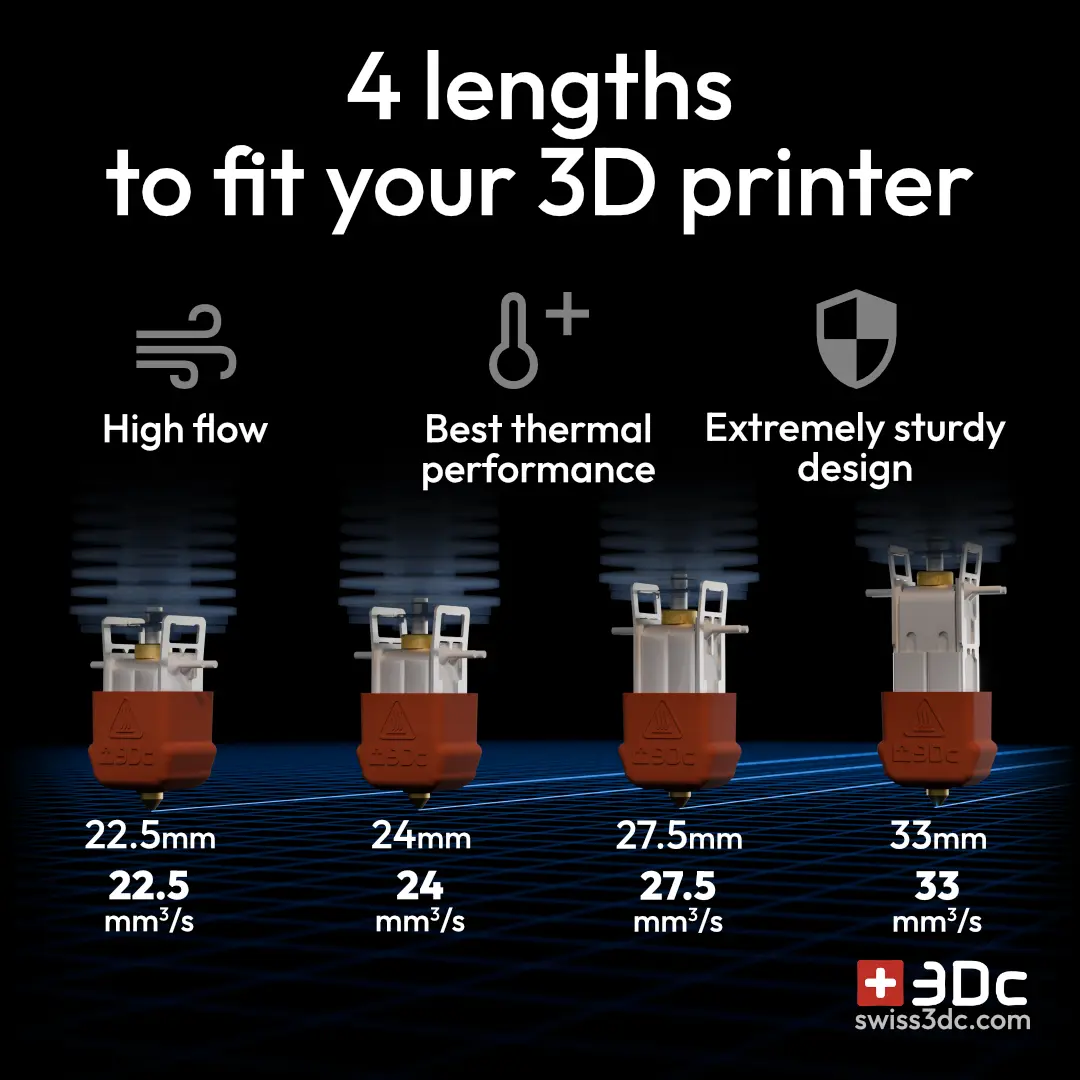

1. Heat Sink (HS)

Original or Adapted heat sink when available?

For some situations, a modified Heat Sink has been developed, to implement the Starlex DHB in place. In this case, no other mechanical changes should be necessary on your tool head.

Modified HS

The modified HS for a DHB 22.5 would be the same nozzle height than the original nozzle height with a much longer melt zone, 22.5mm. The electrical connections will need to be adapted, JST xh2.54/ Molex Microfit 3.0...

Original HS

The Starlex DHB will be added under the original heat sink with a HSC, HSCS and Base Plate. It will increase hot-end Z height, fan shroud will need to be adapted, redesigned by customer, Z height adjusted. The electrical connections will need to be adapted, JST xh2.54 / Molex Microfit 3.0 / 4 pins screw connector ...

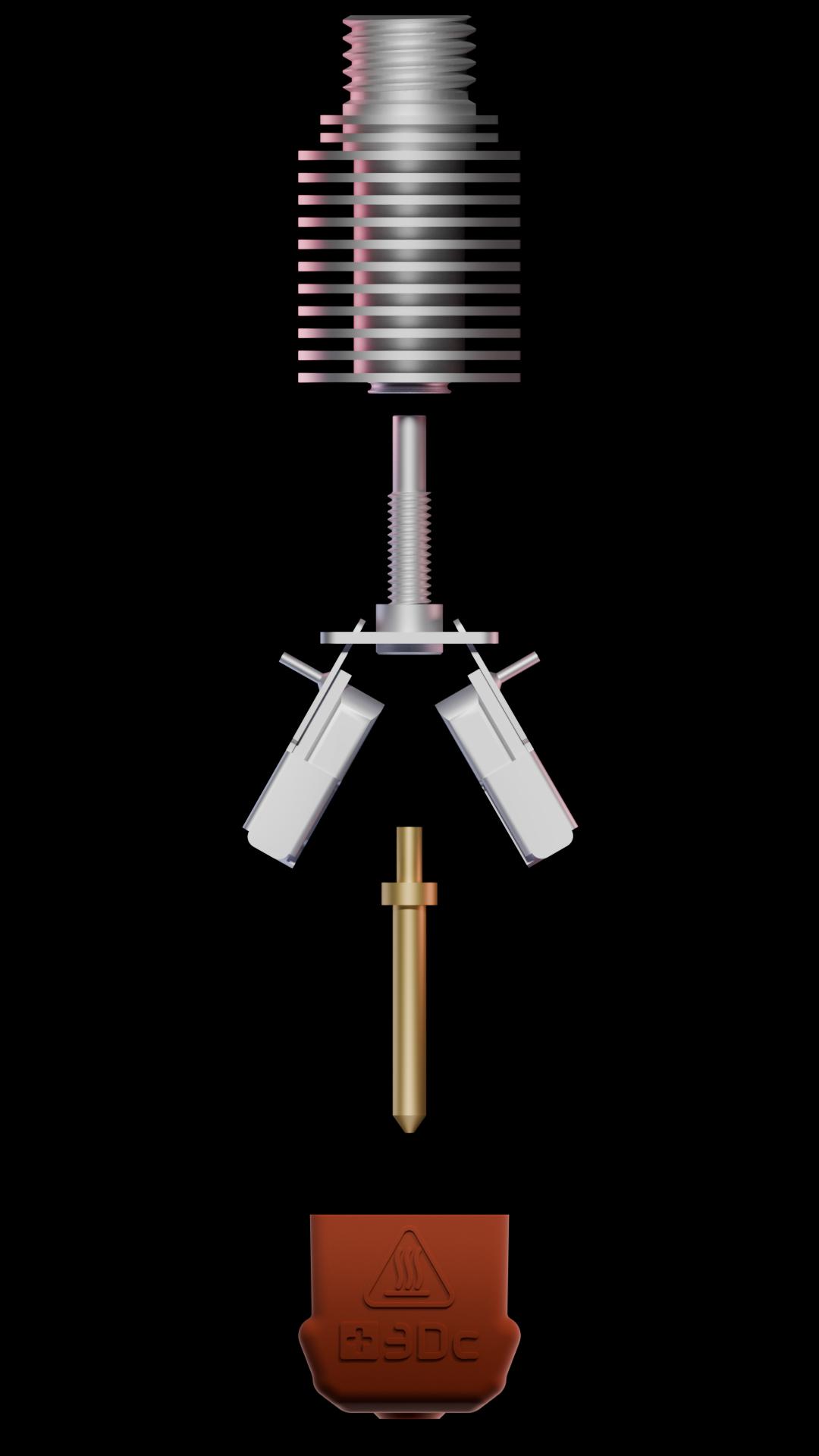

2. Heat Sink Connector (HSC)

The heat sink connector replaces the Heat Break Tube.

Check on your system:

> Threaded mount, Metric size and length

> Cylinder mount, Diameter size and length

3. Heat Sink Connector Spacer (HSCS)

The heat sink connector spacer is necessary when the original heat sink or extruder mount is kept.

To move the two arms of the dual heat block, some space is necessary between the HS and the BP reason we need this spacer.

For some situations, it can also be a ring washer.

> Its diameter depends on the Heat Sink Connector (HSC) diameter.

+1.5mm in height

Shop Heat Sink Connector Spacers

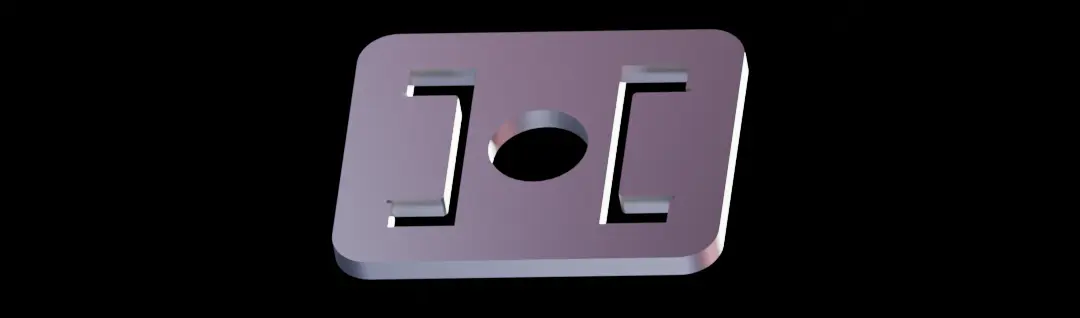

4. Base Plate (BP)

The Base Plate is the most important part.

In stainless steel to reduce heat creep, it is the main holder for the Dual Heat Block Eco-system.

> It's inner diameter depends on the HSC diameter previously defined (D4, D6, D7)

> It's various shapes depends on your Heat Sink

> It can come with a flat groove to "lock" in position and avoid the hot-end to rotate

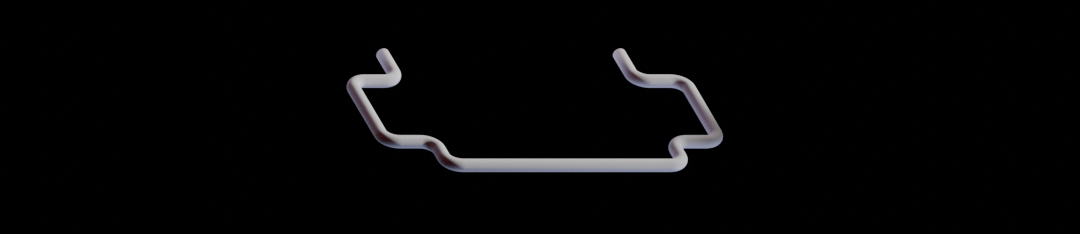

5. Spring

The spring is the part that will hold both heat block arms onto the Base Plate.

Most hot-ends will come with the Inner Spring